Safe, pristine drinking Water

Aquapax is Australia’s leading bulk drinking water supplier for WA’s mining industry, remote worksites and regional communities. Western Australian owned and operated, our 1000L Water Pods use sustainable bag-in-box technology to keep your water fresh and protected from the elements with a guaranteed two-year shelf-life.

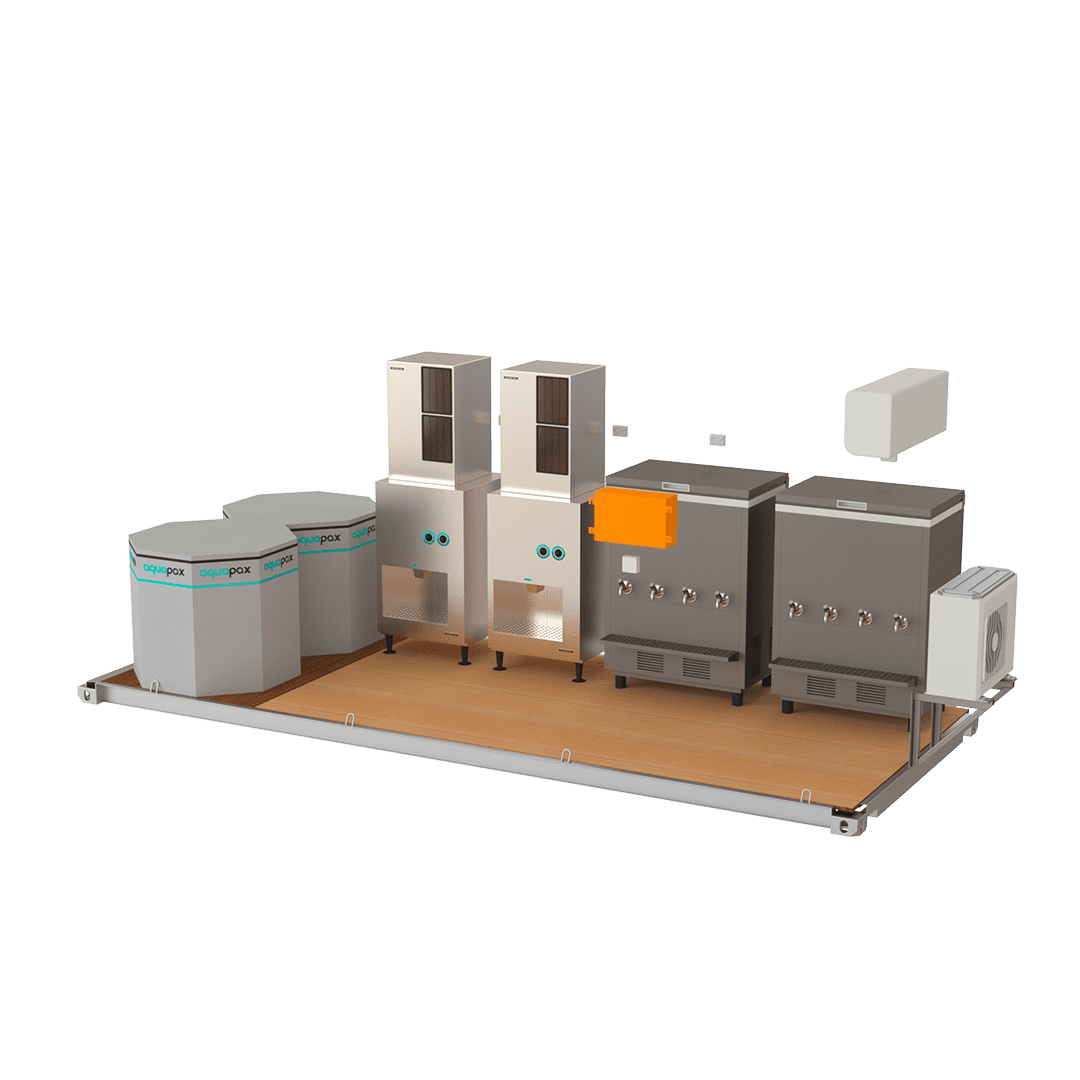

The single-use system can be connected to multiple pods and be pumped into a crib room or site structure. Our water pods reduce plastic waste by 80% and transport emissions by 50%.

Pure Aussie bulk spring Water on-site, Anywhere

Located in Kewdale Western Australia, Aquapax is your local bulk spring water supplier. We source pristine spring water from the Darling Scarp, treated to the highest Australian standards, and pack it into a unique, long-life sustainable bag-in-box which keeps the water tasting fresh for 2 years.

Australia’s most Trusted bulk spring water Supplier

Aquapax is a registered and preferred supplier to some of the biggest names in mining in Australia. We make it our mission to deliver our products anywhere, on time and according to our customer’s requirements.

Australia's Most Trusted Water Supplier

A WA owned and operated family business

Aquapax is owned and operated by Bulk Drinking Water Supplies WA Pty Ltd, a wholly-owned West Australian company.

Since 2012, Aquapax has provided innovative bulk drinking water solutions to customers across Australia. We’re proud to be an industry leader and work with some of the biggest names in mining, construction and beyond to provide fresh bulk drinking water to anywhere in Australia.

Aquapax FAQS

Wondering where our spring water is sourced, how our products work or how we can help your business with bulk spring water solutions? You’ve come to the right place. If you’ve got another burning question, give us a call or send us a message.

Our Perth spring water is sourced right here in W.A from a natural spring in the Darling Ranges. Our source is carefully monitored and tested to ensure our bulk drinking water meets stringent Australian standards at all times.

Bag-in-box packaging utilises a box, bag, and fitment to transport and dispense liquid products both efficiently and without contamination.

Bag: The bag is constructed from layers of film that are sealed together and designed to protect the product quality and keep it safe inside from filling through end use.

Spout: The foundation of our all bag-in-box fitments, this plastic-framed opening is sealed into the bag when it’s made and is the entry point for filling the product into the bag. After filling, bag spouts are covered by either a simple cap, dispensing tap, or connector and fitment depending on their intended end-use.

Box: the outer package that holds the capped and filled bag. This can be anything from a simple cardboard box to an industrial-sized steel drum.

The bag is first filled with liquid product, and then a fitment is placed to secure the packaging. The bag is then placed in a box to ensure safety in transportation and dispensing.

Bag-in-box history

Bag-in-box was pioneered and patented by William R. Scholle in 1955, and it was initially used to safely transport battery acid to automotive filling stations and repair shops. While only starting off in the automotive industry, this packaging system quickly spread to other industries. After the aseptic filling process was perfected in 1956, bag-in-box was able to expand into working with food and beverage products.

You sure can! Please get in touch today for equipment hire and expert advice for any project in Perth and throughout Western Australia.

There are three ways the 1000L water pods can be dispensed:

- Gravity Feed (straight from the pod’s outlet valve)

- Connect to an Aquapax Rehydration Station

- Connect to constant pressure water pump

We charge for bulk water delivery in Perth. Delivery of Heavy Pallets ( 1000L Water Pods and Pallets of Bulk Drinking Water) to the Perth metro area is charged at a percentage of the total invoice value – this percentage varies depending on macroeconomic conditions. Small pallets delivered within the Perth metro area are charged at a flat rate (rate available at checkout or upon quotation). Bulk drinking water delivery outside the Perth metro area needs to be quoted on a case-by-case basis. For customers in remote areas (mine sites etc) with their own established transport company accounts, we recommend utilising these providers. We can either drop them off at the transport providers’ depots in Perth or, goods can be picked up from our production facility in Kewdale.

Lead times depend on the quantity of 1000L water pods required. Please use the timeframes below as a guide.

1 – 25 Pods: 2 Working Days

25 – 50 Pods: 5 Working Days

50+ Pods: Up to 10 Working Days

Our Products

Sourced from Australia’s freshest springs, our products uses sustainable bag-in-a-box technology that is eco-friendly and recyclable. Our 1000L Water Pods are a friendly bulk water solution with a range of dispensing equipment and plumbing products available.